Description

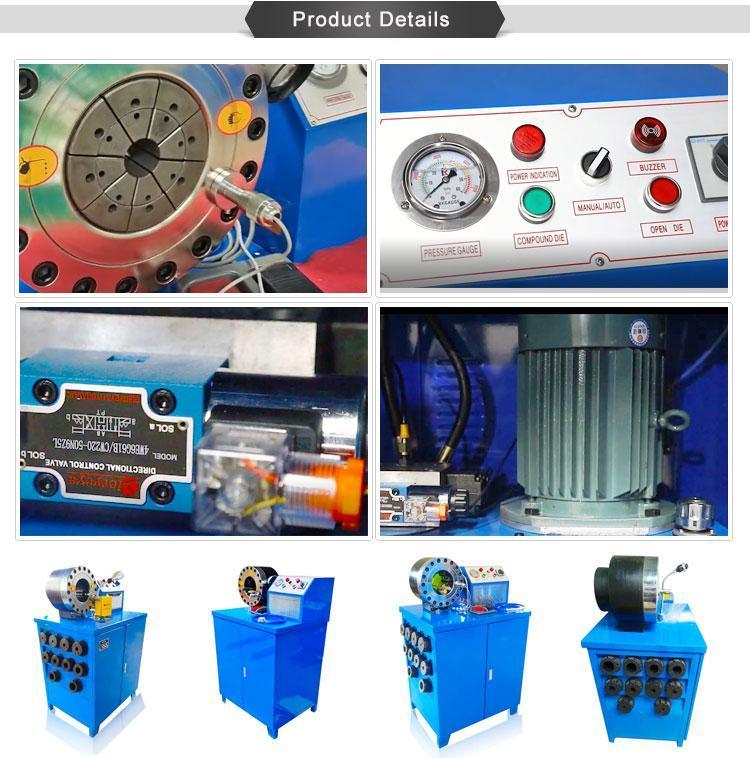

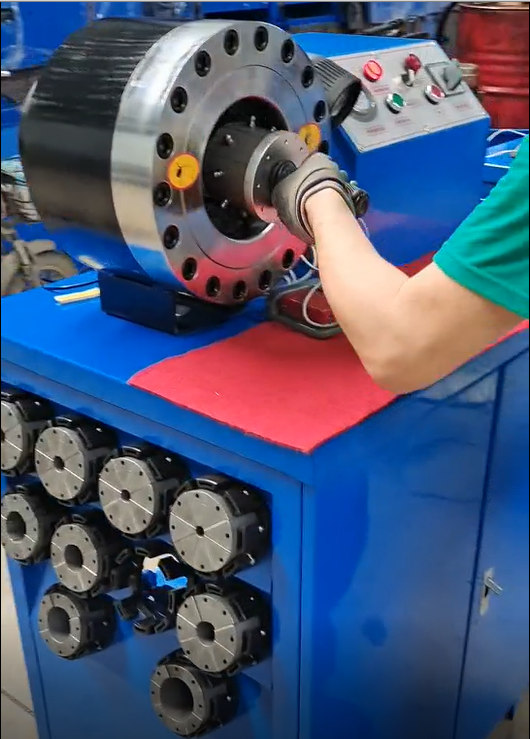

This hose crimping machine is mainly used for buckling processing for high pressure rubber pipe assembly in the mechanical engineering. It can also be used for buckling the two-way bends, especially large bends and irregular shape bends.This machine features small and portable appearance, big force, low noise and easy to operate. The buckling amount can be precise adjusted through a scale. It makes the mould base division to be more even through the double inclined plane eight-flap mould seat equipped with a high accuracy guiding device.

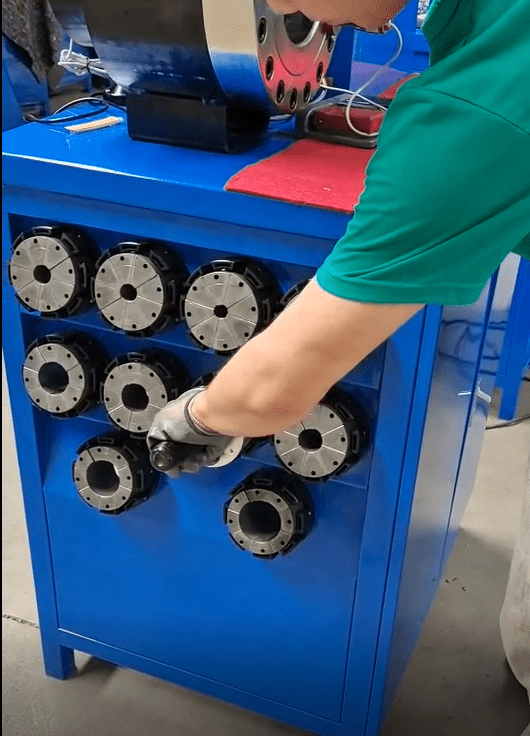

The side of the machine is specially designed to add mold holders to facilitate the access and replacement of the molds, and the machine operation is more convenient and efficient.

The mold opening speed is fast, the weight is light, and the cost is reduced, and is not easy to be damaged, and reduces maintenance costs.

The machine is equipped with a high box, which provides a wider space for the machine, making it easy to place machine parts and other necessary tools.

| Model | DSG250 | DSG250A | DSG250-1 |

| Crimping range(_mm) | 6-51mm | 6-87mm | 6-51mm |

| Qty of dies(set) | 10 | 13 | 10 |

| Crimping precision(mm) | 0.01mm | 0.01mm | 0.01mm |

| Displacement(L) | 5L | 19L | 5L |

| System pressure(Mpa) | 31.5Mpa | 31.5Mpa | 31.5Mpa |

| Power(Kw) | 4Kw | 4Kw | 3Kw |

| Voltage(V) | 220V | 380V | 380V |

| Crimping pressure(T) | 640T | 536T | 500T |

| Efficiency(pc/h) | 200pc/h | 1000pc/h | 200pc/h |

| Dimension(mm) | 700*900*1400 | 800*650*1320 | 800*640*1300 |

| Weight(Kg) | 360KG | 320KG | 300KG |

Replace the mold progress

Reviews

There are no reviews yet.